Linerless is an automatic print and apply system applying the last printed label typically on still or moving boxes, packets, trays, pharma packets, pallets and many other products.

Linerless prints any type of code, images and variable data coming from the packaging line and applied the last printed label.

Linerless is a state-of-the-art labeller, typically installed in the end-of-the-line, and especially is an ecologic labeller. Indeed, thanks to linerless label, it offers the following advantages:

- Not even one metre of silicon liner to collect or dispose of;

- Lower purchase cost;

- Reduction of weight and occupied space, with consequent savings on transport and stocks;

- Greater capacity of the reels with reduction of replacement operations.

Technical specifications

- Speed and liner maximum width depending on print module installed;

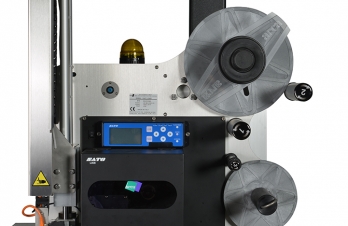

- Built on a solid anodized aluminum alloy plate, with all the components protected by the rear 61 Shore hardness light polymer shell. A safe and most robust machine, designed to last over time;

- 4 pneumatic solenoid valves with independent blast and suction, to reduce air consumption (suction is suspended when the label is not on the pad);

- Emergency push button;

- Large diameter (360mm / 14.17”) reel for long duration;

- Paper path rollers numbered for quick loading:

- Expansion rewinder manual;

- “U arm” for universal positioning;

- Configured for the integration of a Sato or Zebra print module built in control panel, with luminous LEDs and soft keys. Otherwise, in the Advanced version, an independent control unit which can be located wherever most practical for the operator (cable length: 3 metres / 9.84 feet)

Linerless has advanced electronics so use it is very simple, thanks to the concentration of all the adjustments and controls in a single panel including:

- Four function buttons: alarm reset, stand by, printing and dispensing of a label and label application (cylinder movement);

- Four luminous LEDs to signal machine state: working/stand-by, failure, product detection and printing in process;

- Two flow regulators, to control the exit and return speed of the pneumatic actuator;

- Two flow regulators to control the suction and holding force (Air Assist) of the label, at the dispensing stage.