This Weight Controller is extremely versatile and functional, great for small and medium format products.

With a maximum capacity of 1600 gr, accuracy of ± 0.5 gr and an output rate of 300 ppm, it is the ideal instrument for the most common weight control requirements, for a huge variety of packages of different shapes and sizes.

Manufactured entirely in stainless steel, it has an IP54 degree of protection and a high degree of customisation thanks to the numerous options available. Double load cell weighing system.

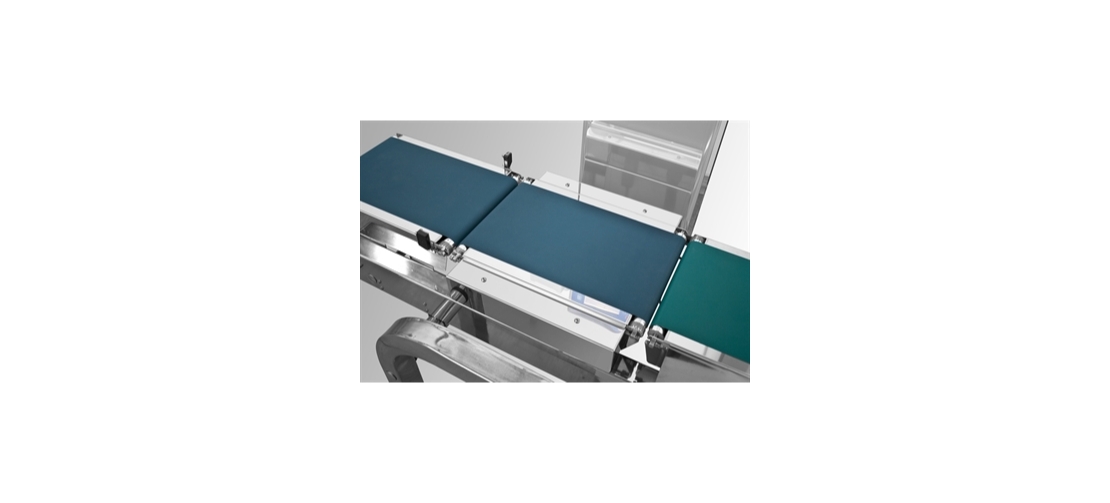

Dual Weighing System

The weight is measured using a double load cell system. The two cells are positioned on the sides of the weighing plate, which allows the machine to be cleaned more quickly and efficiently than under other conditions, thereby reducing maintenance costs and production line downtimes. Furthermore, this system ensures extremely high precision even at high speeds.

Simple and Functional Electronics

Digital alphanumeric display, complete with auto-calibration device, storage capacity of up to 100 production programs and 2 RS232 C type ports. Access is protected by multilevel password, reducing human error.

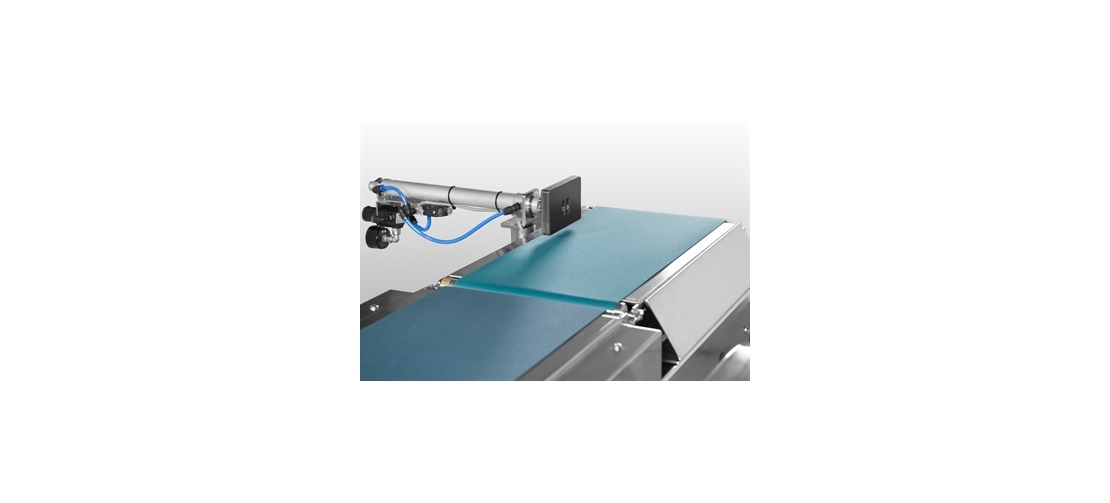

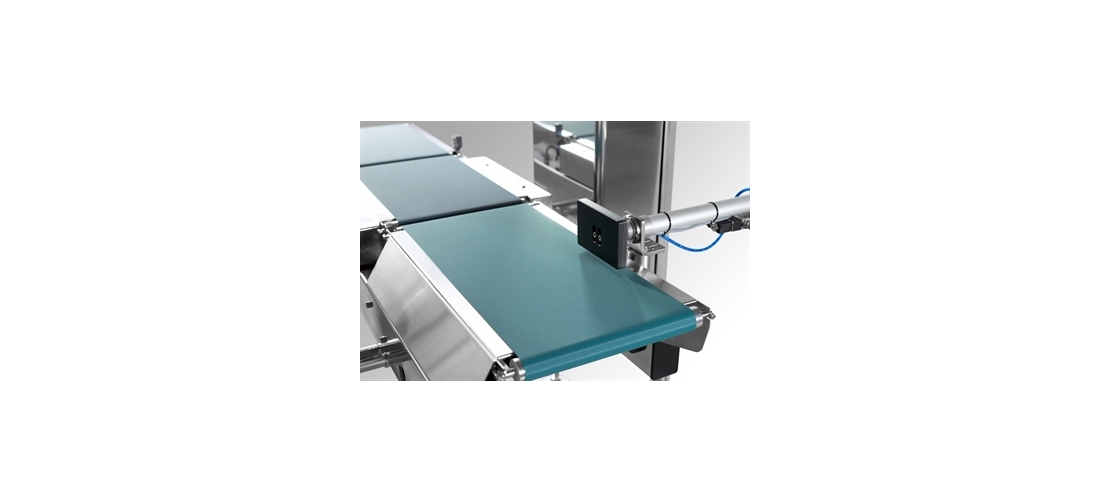

Stable, Safe and Easy-Maintenance Mechanics

This Checkweigher is composed of 3 conveyors, feeder, scale and feeder, supported by a stainless steel structure, which gives stability to the equipment, eliminating possible vibrations and disturbances. All models meet the protection standard, from IP54 to IP65.

Quality

Equipment made in Italy, manufactured entirely in stainless steel, capable of withstanding intense washing cycles, which can be done extremely quickly thanks to the quick-disassembly plates.

Compliance with Standards

This equipment complies with ISO-FDA HACCP, key directives (including but not limited to: OIML R51- MID directives, FDA approvals, FAT/SAT IQ/OQ) and meets customer guidelines and standards (including but not limited to: BRC and Marks & Spencer.

Return on Investment

Prisma's range of equipment allows for major savings, drastically reducing product waste, false detections or production stoppages. Everything translates into a fast return on investment, thanks to the high quality of the materials and the durability of the state-of-the-art equipment.

Weighing Range

Up to 1600 gDecimal places

0.5 grLinear Speed

Up to 100 m/minCadence

Up to 300 ppmAccuracy

± 0.5 grCompressed air consumption (product rejection)

1 NlPower supply

230 V 50/60 Hz single phaseElectrical consumption

700 WClimatic Environment

5ºC to 40ºC