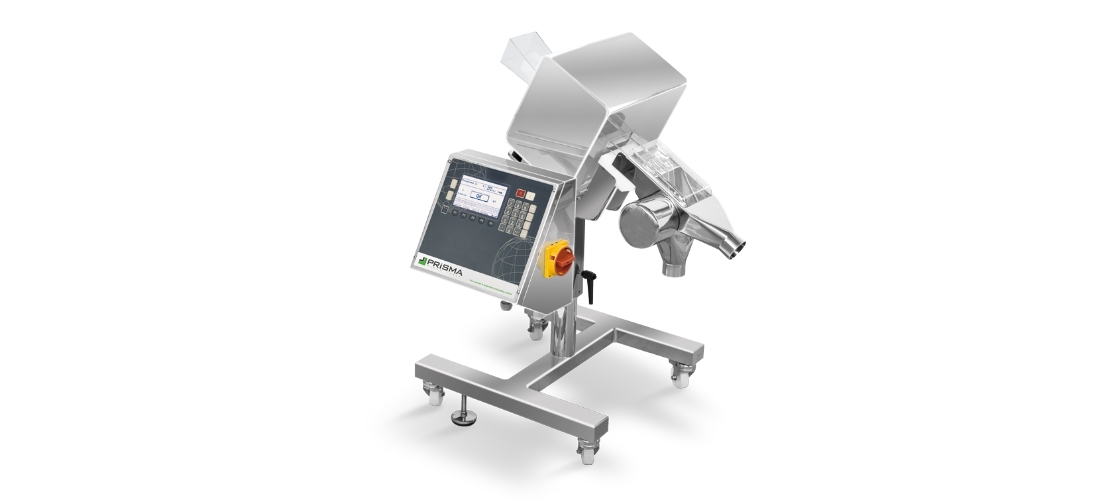

Metal Detector for the Pharmaceutical Industry, for small and high flow rate products, such as tablets and capsules.

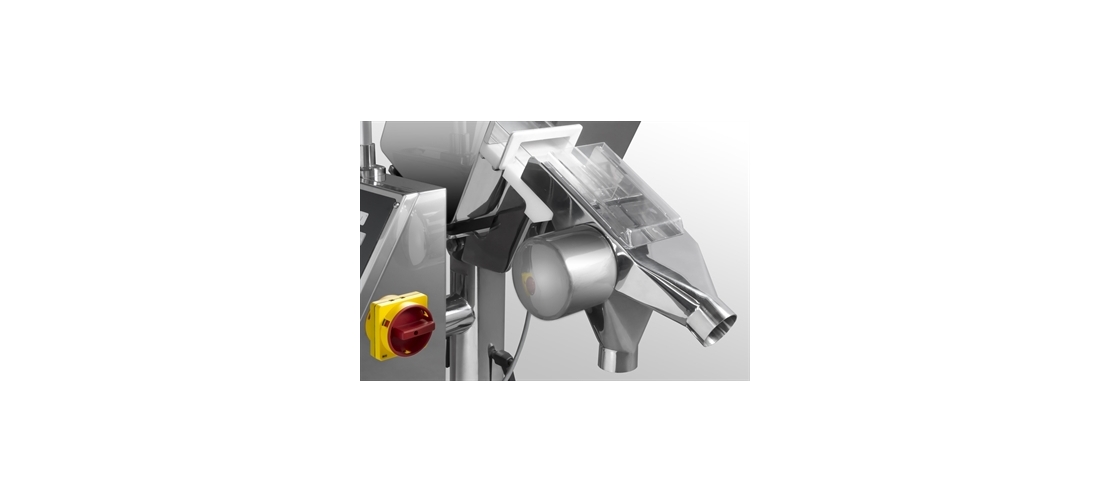

This equipment has been specifically designed to meet the specific inspection requirements of the pharmaceutical sector. An inclined duct made of inert material, easily removable and suitable for direct contact with the product, passes through the coil of the metal detector. If a metal contaminant is detected while the product is in transit, a safety flap is activated and diverts the contaminant out of the production flow.

Equipped with regulators, which make it highly adaptable, this metal detector is capable of checking 10,000 pieces/minute and can detect any type of metal contaminant, ferrous, non-ferrous or stainless.

Multi-frequency technology combined with advanced functions guarantee high level performance and comply with the standards in force for Pharmaceutical Metal Detection Systems.

Multi-frequency technology

It results in a high level of immunity against environmental interference and an extremely high sensitivity to all magnetic and non-magnetic metals, including stainless metals, thus guaranteeing high level performances.

Simple and Functional Electronics

Digital alphanumeric display, with self-checking, automatic balancing and tracking functions. Digital operating principle of two-dimensional image. Possibility of phase adjustment and storage of up to 100 programs. It has an RS232 C type port. Access is protected by a multi-level password, so as to reduce human error to a minimum.

Stable, Safe and Easy-Maintenance Mechanics

Equipment consisting of an inclined duct, which passes through the metal detector coil, easily removable and can be completely sanitised. Control panel with IP54 protection and main support structure in stainless steel, with ballasted base to increase insensitivity to vibrations and ensure mechanical stability. The structure allows adjusting the product feeding height, the angle of inclination and the movement of the unit by means of wheels. Equipment available with or without rejection box.

Quality

Equipment made in Italy, manufactured entirely in stainless steel, capable of withstanding intense washing cycles, which can be done extremely quickly thanks to the quick-disassembly plates.

Compliance with Standards

This equipment complies with ISO-FDA HACCP, major pharmaceutical directives (including but not limited to: FDA approvals, FAT/SAT IQ/OQ) and meets current standards for Pharmaceutical Metal Detection Systems and customer guidelines and standards (including but not limited to: BRC and Mark & Spencer).

Return on Investment

Prisma's range of equipment allows for major savings, drastically reducing product waste, false detections or production stoppages. Everything translates into a fast return on investment, thanks to the high quality of the materials and the durability of the state-of-the-art equipment.

Power supply

230 V 50/60 Hz Single PhaseElectric consumption

200 WClimatic Environment

5ºC to 40ºC