Sealing Length

5 sealing bar sizes assure maximum flexibility

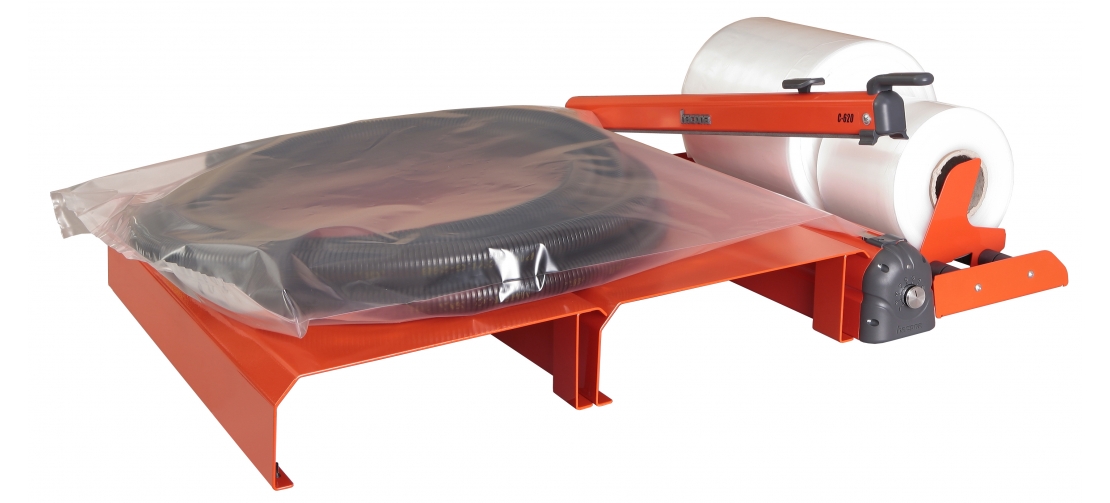

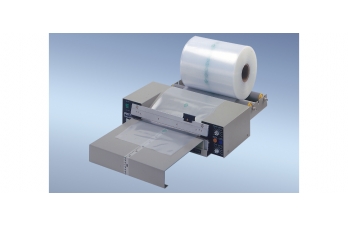

The C – type impulse heat-sealing machines are produced in 5 different sealing bar length. This wide product range assures maximum flexibility to choose the right machine size for the right application. For small bag sizes the C – 220 impulse film sealing machine offers best place saving solution. If all kind of different bag sizes are used in packaging, then the C – 820 offers the most flexible solution, because all bag sizes can be sealed on one machine.

Choose the right machine size referring to the biggest bag size used in packaging process.

|

Machine Type |

Sealing Length (mm) |

Power (W) |

|

C – 220 |

220 |

180 |

|

C – 320 |

320 |

218 |

|

C – 420 |

420 |

248 |

|

C – 620 |

620 |

365 |

|

C – 820 |

820 |

468 |

All of the C – type impulse film sealing machines are working on impulse sealing principle. The sealing wire gets only hot when sealing bar is closed.

General information: All film sealing machines, including the C – type are designed to seal also narrow packaging films with a wide sealing bar size!

Example: With a C – 820 impulse film sealing machine it is possible to seal very narrow, even 50 mm (2 inches) or 100 mm (4 inches) wide packaging film. No mechanical adjustments are needed to work with 50 mm (2 inches) or even with the 820 mm (32 inches) packaging film.

The sealable maximum material thickness (absolute material thickness) for all C – type impulse film sealing machines is:

PE Polyethilene 200 micron

PP Polypropylene 200 micron

Multi layer - laminated film 100 micron

(depending on the type of the lamination!)

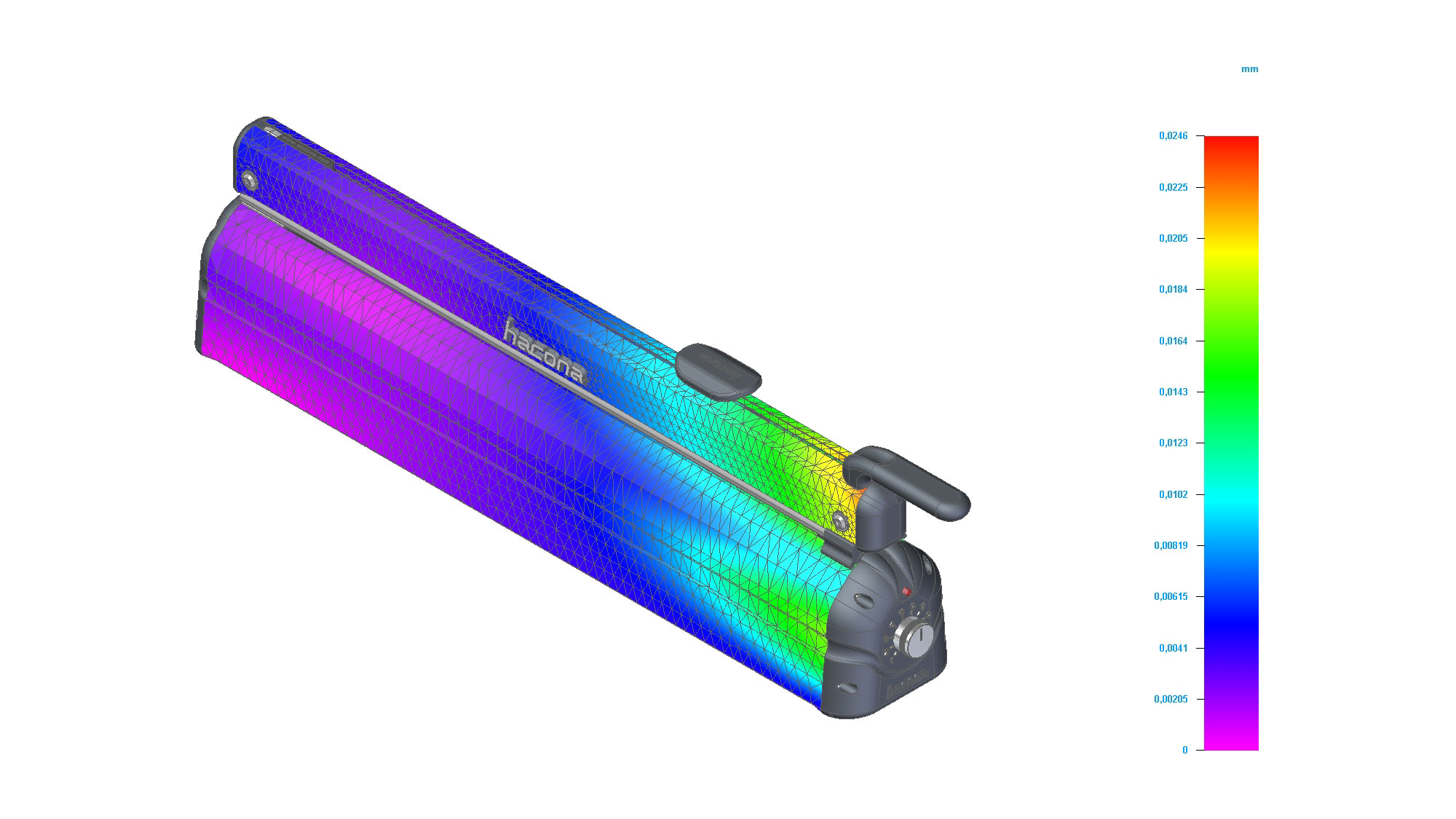

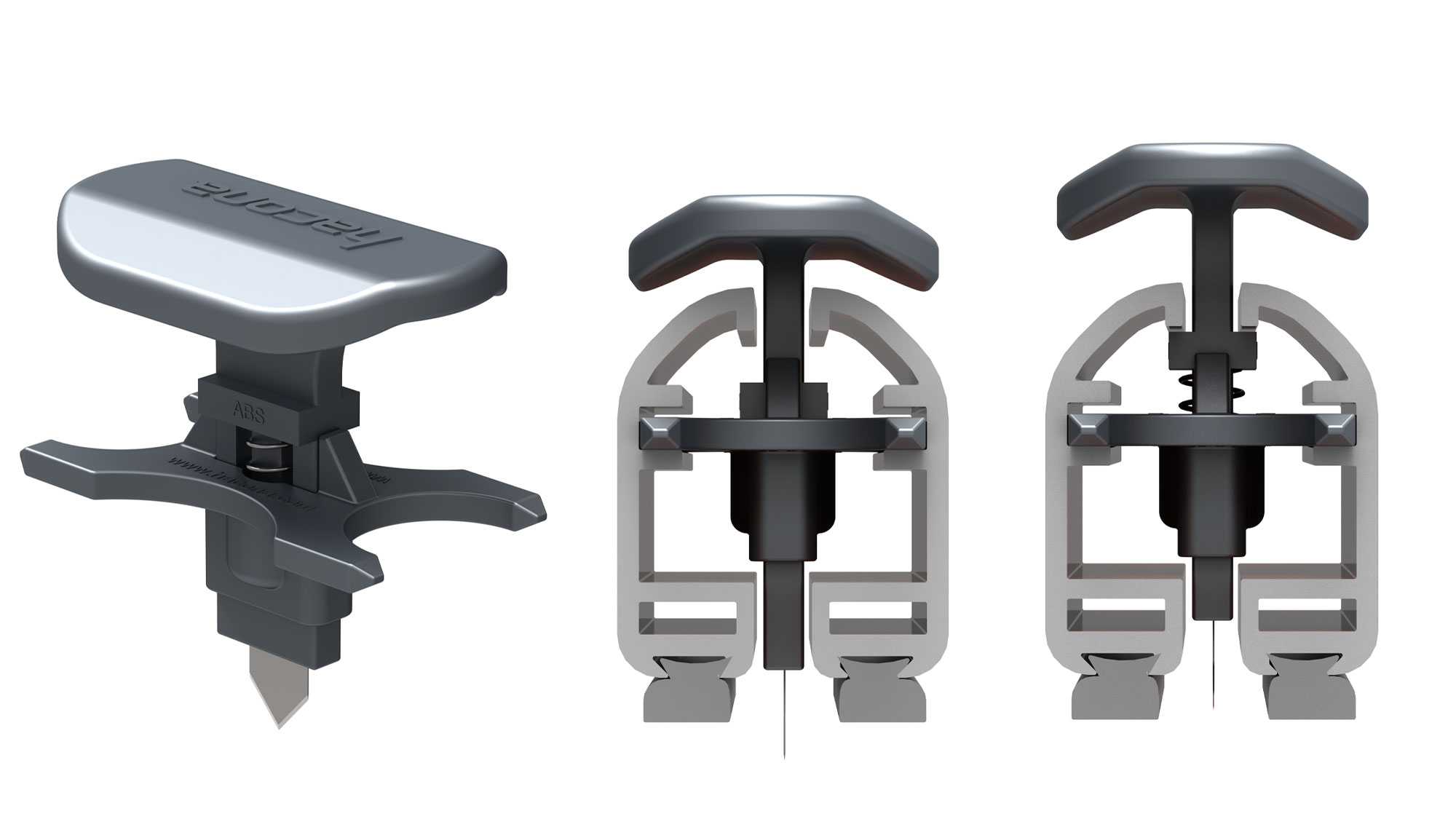

With this revolutionary new sealing bar guiding funnel technology, we make the closing of the sealing bar safe and stable.

Thanks to the specially designed sealing bar closing handle with funnel guiding, even the longer sealing bars (C – 620 and C – 820) are guided in a smooth and safe way to the parallel closing position.

With this funnel we assure that the complete length of the sealing bar is always exactly above the sealing wire. The sealing bar handle and the funnel are made of ultra-strong plastic with fibre and technology.

By closing the sealing bar with the handle in the front right sealing bar, pressure is always guaranteed.

Machine Frame

Ultra-strong magnesium-aluminium body

The body of the machine and the sealing bar of each C – Type impulse seat sealer is made of ultra-strong magnesium-aluminium profile. This technology assures super strong base and absolute flat surface for the special designed impulse sealing wire. In parallel we guarantee with the special designed aluminium ribs inside the frame also a proper and fast cooling of the sealing wires after the sealing cycle is finished.

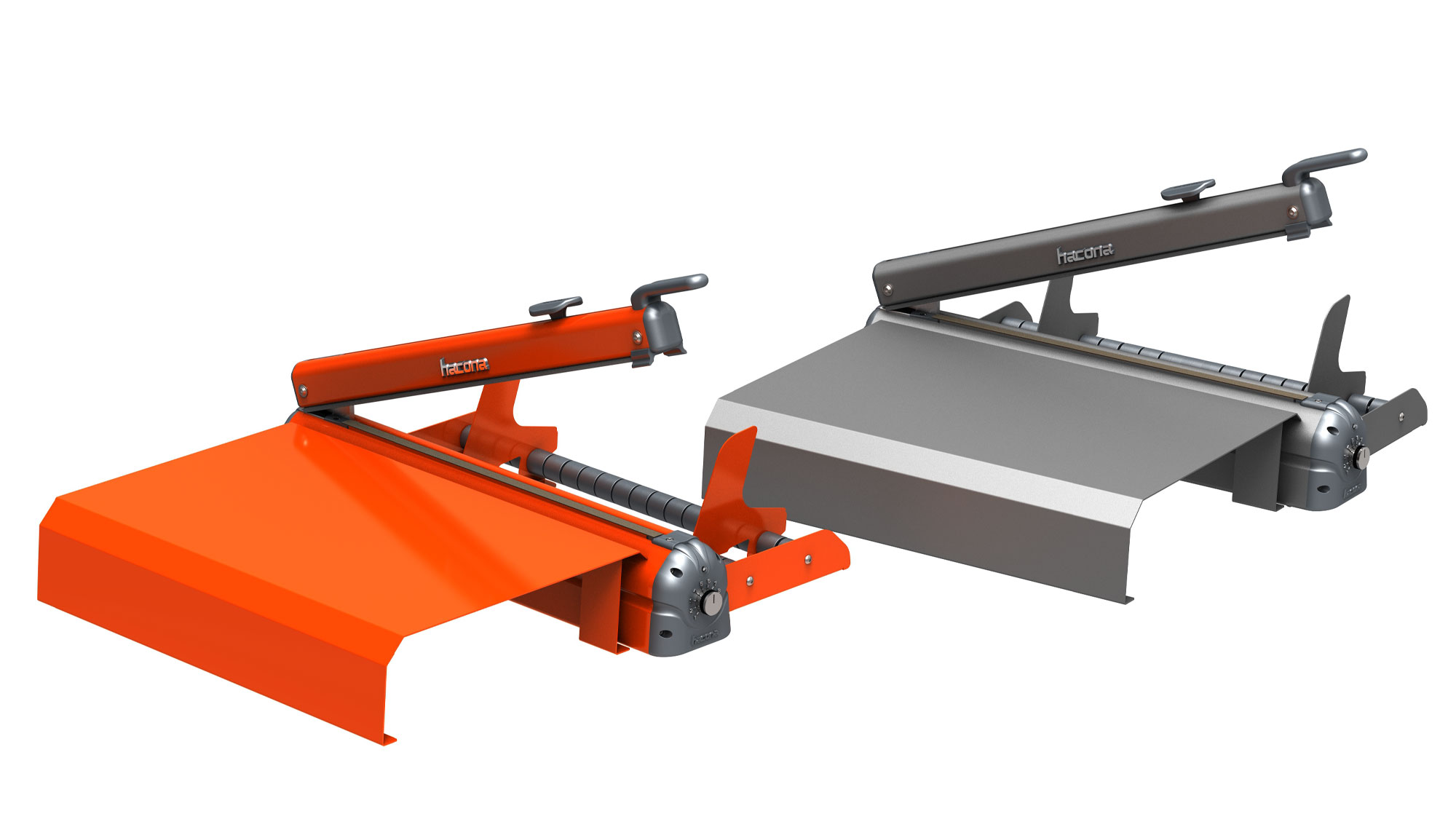

C – Type impulse sealing machines with powder painted surface

The entire machine is designed to assure the highest safety. The machine body and the connecting parts are assembled so precisely, that there’s not even a single gap between them. No free running cables and no openings on the machine frame.

CI – Type impulse sealing machines with silver anodized surface

All CI – Type impulse sealing machines can be used in food, pharmaceutical and chemical industry. By anodizing (surface treatment) the machine frame, the surface of the aluminium profile becomes completely smooth and strengthened. With this surface treatment, the CI – Type film sealing machine frame is now even more resistant against scratches and mechanical impact.

Impulse Film Sealing Technology

A technology without compromise: The specially designed C – Type sealing wire tensioning systems assure at any temperature level an optimised sealing wire tension. At high temperature values the sealing wire expands itself. Our sealing wire tensioning system is designed to apply optimal tension at any temperature level and assure a free movement of the sealing wire in longitudinal direction.

All C – Type impulse heat sealers work with a 2.5 mm wide impulse sealing wire. The sealing length depends always on the size of the machine. All thermoplastic (heat sealable) films up to 200-micron total material thickness can be sealed easily and air tight. The total surface of the sealing wire is PTFE. This avoids sticking of the bag material to the sealing wire.

The C – Type impulse heat sealers have an integrated specially designed safety cutting knife system. This cutting knife system enables to produce bags from tubular film or to cut the rest of the film off the bag after sealing.

Sealing wire temperature & Time control

All C-type impulse heat sealers can be adjusted in sealing time from 1 – 10 values. The sealing wire is time controlled. By adjusting the sealing time, the temperature will automatically increase in parallel. The sealing temperature and cooling time cannot be set!

A LED light above the turning knob shows the present status of the machine. If the light is off, then the C-type impulse heat sealer is unplugged (the machine is shut OFF). In this condition the machine can be stored or repaired.

By plugging in the machine the LED light will turn yellow. The machine is in standby mode.

The average consumption in standby mode is less than 1 W (electrical power).

To work with the machine and to seal a bag, the sealing bar must be closed. The LED light will turn from yellow to red.

Red light shows that the machine is sealing. After the adjusted time the sealing will stop, and the red LED light will turn yellow again.

For a perfect sealing result we always suggest keeping the sealing bars closed under pressure for an additional 1 – 2 seconds after the sealing is finished (the red lights turn yellow again).

Safety

• SAFETY cutting knife system

All C – type impulse film sealing machines have an integrated safety cutting knife to cut off the rest of the bag above the sealing. The cutting knife can be used also to produce bags from tubular film.

The sharp cutting knife is safely positioned inside the aluminium sealing bar. This assures, that the operator cannot cut or hurt himself with the knife before it is activated.

In order to activate the cutting knife the operator has to push down the knife and move it along the complete sealing bar length. After releasing the blade it will slide back into its safe position.

• Impulse film sealing technology

The sealing wire heats up only when the sealing bars are closed. The sealing is activated when the sealing bars are totally closed and the LED light turns from yellow to red. If the operator opens the sealing bar before the sealing cycle is finished, the heating of the sealing wires will be shut off automatically. NO risk of getting burn injuries.

In stand by mode the machine consumes only 1 W electrical power.

• Totally closed machine body

The entire machine frame is totally closed. There is not even a slight opening or gap on the machine body. There are no free running electrical cables. Each electrical connection is properly hidden.

The sealing wire is covered with PTFE tape on the total length.

Modular System

Each C-type heat sealer can be equipped with following accessories:

• Working table

• Film holding rolls with guiding plates

Technical Data

|

Technical data |

C-220/CI-220 |

C-320/CI-320 |

C-420/CI-420 |

C-620/CI-620 |

C-820/CI-820 |

|

Max. sealing length [mm] |

220 |

320 |

420 |

620 |

820 |

|

Sealing width [mm] |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

|

Max. sealable film width [mm] |

200 |

300 |

400 |

600 |

800 |

|

Max. cutting width [mm] |

200 |

300 |

400 |

600 |

800 |

|

IP protection class [IP] |

IP 23 |

IP 23 |

IP 23 |

IP 23 |

IP 23 |

|

Electrical connection [V, Hz] |

230, 50/60 |

230, 50/60 |

230, 50/60 |

230, 50/60 |

230, 50/60

|

|

Power [W] |

180 |

218 |

248 |

365 |

468 |

|

Size of machine WxDxH [mm] |

400x95x300 |

520x95x320 |

630x95x360 |

840x95x270 |

1030x95x320

|

|

Weight of machine [kg] |

3.30 |

3.80 |

4.00 |

5.10 |

7.20 |