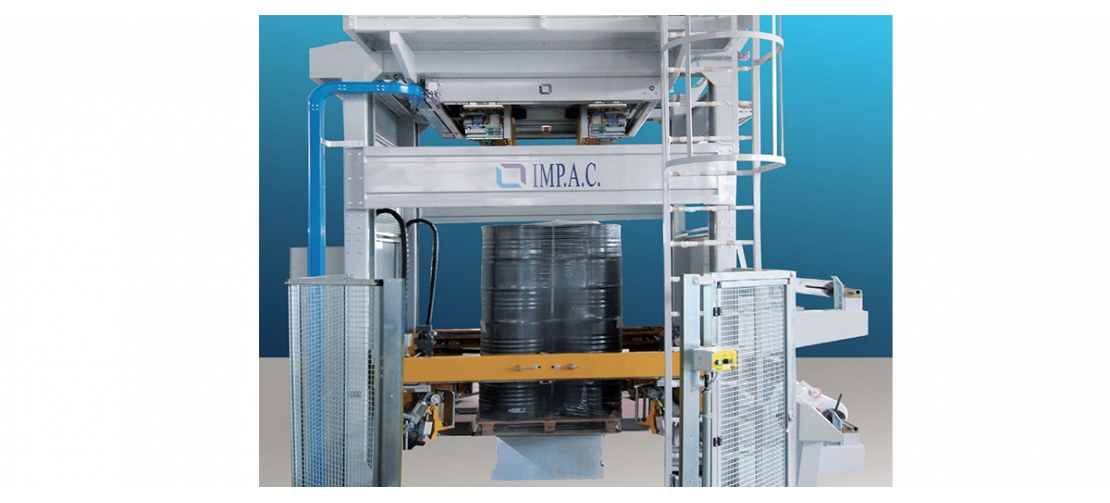

The IMP.A.C STRETCH APT pallet hooding machine allows maximum stabilization and protection of the pallets by extending the hood to the end of the pallet. It is the ideal solution for medium production lines (up to 30 pallets/hour).

It also allows the hooding of pallets with unstable products, which do not allow packaging with traditional pallet wrappers. The film is applied through the cold extension technique. The equipment adapts automatically to the height of each pallet, adapting the length of each hood optimally.

The main stages of the production cycle:

1. Manual positioning and identification of pallet dimensions;

2. Film unwinding;

3. Opening of the film and fixation in 4 points;

4. Cutting and welding of the film, forming the hood with optimized length for the pallet in question;

5. Mechanical shrinkage of the film through motorized wheels allocated in the 4 corners;

6. Extension of the hood with contour control by following the mobile structure;

7. Release of the hood under the pallet;

8. Manual pallet output.

Pallet Dimensions

Max. 1200 x 1200 mmPallet Height

Max. 2100 mm Min. 300 mmType of Film

Elastic, extensible polyethyleneFilm Thickness

Max. 200 micron Min. 80 micronProduction Capacity

Up to 30 pallets/hourCompressed Air Pressure

6 barCompressed Air Consumption

120 Nl/minVoltage

24 VApproximate weight

4500 kg