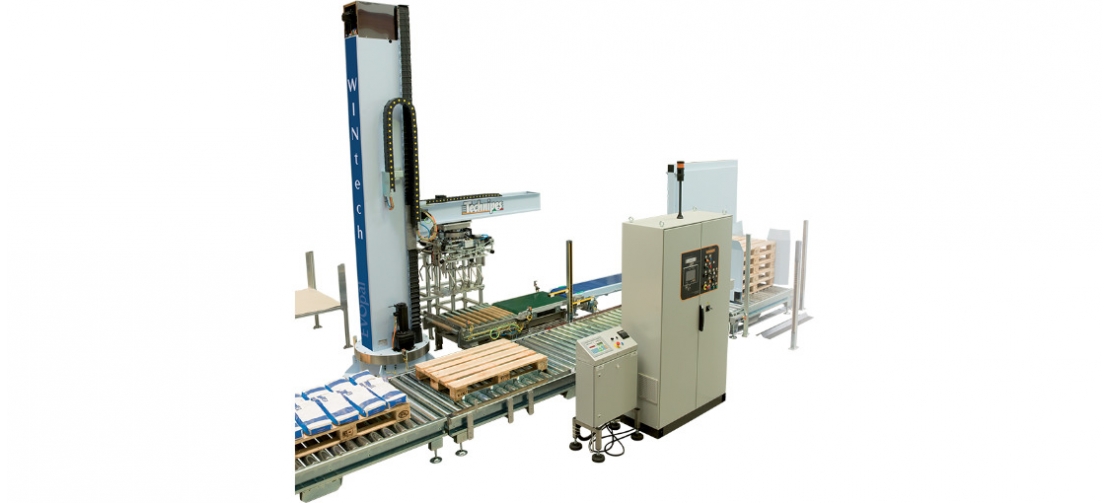

Owing to its small size and its versatility of use, it turns out to be the ideal solution for all those who cannot install a conventional palletizer because they do not have enough space.

For very low output capacity up to 550÷600 bags/h, it is a balanced solution between investment and palletizing quality. WINtech has several different motors in order to determine different output capacities. The current models are the following: WINtech-4, WINtech-5, WINtech-7, WINtech-8, WINtech-10. WINtech is the optimum solution for palletizing open-mouth bags, where shapes are not perfectly square, and palletization with over lapping of the empty bag part is required.

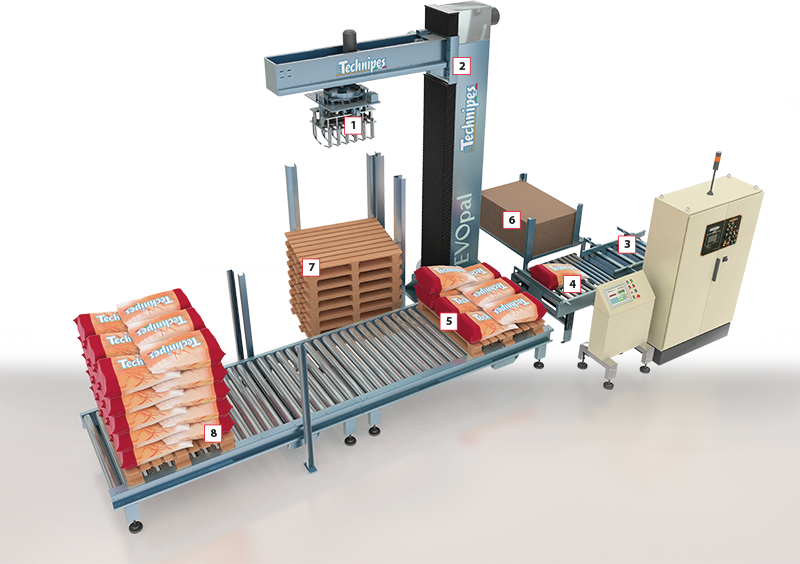

- PREtech Multifunctional plier unit for bags, slip-sheet and pallets.

- Robot 4-axis palletizing column.

- Square roll roller conveyor Required for granular products. It allows product to be perfectly distributed inside the bag before picking up.

- Bag grip roller conveyor Bag pick-up station with bag centering.

- Palletizing station Bag release area in the preset configuration of layer.

- Slip-sheet magazine To store slip-sheet to be released onto the formed layer.

- Empty pallet magazine Area intended for empty pallets.

- Outfeed roller conveyor Unloading roller conveyor of palletized pallet.

Optionals:

WINtech was developed to meet all palletizing needs determined by spaces which are often very small, or limited modularity and versatility. WINtech can consist of modules obtained by assembling the various stations together in order to determine the most suitable shape to meet the requirements of each user, thus allowing it to be enlarged and upgraded afterwards. The high quality used in its manufacturing makes WINtech a reliable robot where maintenance cost are very low.

PREtech – Multifunctional plier head

Multiple plier head to pick up the bag to be palletized, empty bags and slip-sheet (if any). When bag is released, it is pressed by means of the pneumatic control pressing device to improve its stability.

DUOtech – Automatic change-over of processing head

WINtech may be equipped with a double heads according to the package to be palletized and layer configuration. This attachment performs plier change-over automatically without any intervention of an operator.

Automatic empty pallets magazine

Especially in the high production speeds, WINtech can be outfitted with empty pallet magazine having capacity up to 15 empty pallets with automatic transfer of empty pallets into palletizing area.