Welding - Method

BMB packaging machines offer solutions that guarantee perfect container welding and total protection against mechanical and external stress. They are able to weld trays made of different materials, such as plastic, aluminum, cardboard and foam. Solder-only packaging provides packaging that reliably protects the product from physical and environmental stress, moisture and UV light. Soldering alone is a type of packaging particularly suitable for non-food products and industrial, medical and pharmaceutical products or for food that does not require long shelf life. All BMB packaging machines are equipped to pack in welding only and obtain impeccable packages in compliance with the best quality standards.

Modes of use

ATM Packaging Technology

BMB supports the customer in selecting the most suitable solution. Our proposal consists in innovative and customized solutions in every phase of the packaging in Protective Atmosphere to achieve maximum results. The quality of the packaging process in Protective Atmosphere (ATM) plays a fundamental role in guaranteeing the prolongation of shelf life in a natural way.The principle of this technology is to replace the air in the package with a gas mixture. The shelf life of the product is extended up to four, five times or more compared to the shelf life.One of the advantages of packaging in a Protective Atmosphere is that it preserves and increases safety and protection.This type of packaging can be obtained using all thermosealers, thermoforming packaging machines, and vacuum chamber packers, BMB.

Modes of use

Vacuum-packing - Method

Vacuum packaging prolongs the shelf life of the products. The maintenance of the organic product thus has a prolonged life span. With the vacuum technique, the oxidation process is inexorably slowed down. This prevents the development of microbacteria and preserves the product's freshness for longer. Thanks to the vacuum, the product is also fixed to the packaging in order to create additional protection. All BMB machine lines can be used to vacuum-pack any type of material and consistency. A protected and perfectly preserved end product is guaranteed.

Modes of use

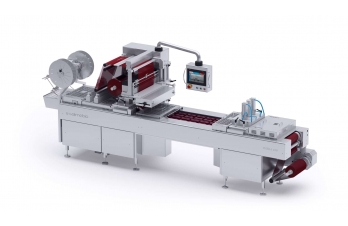

Fully automated machine for vacuum packing and/or MAP packing products with any type of film. Conceived and manufactured with the most modern design and construction technologies, it offers high performance to guarantee the operator safety, reliability and precision over time.

Suitable for any working environment, it ensures easy and fast cleaning and maintenance operations.

Microform exists in 4 different versions: 320, 360, 420, 480.

The difference between each model lies in the width of the film to be used: for example, for the Maxiform 320 model, it must be used 320 mm wide film, 360 mm wide film is used for the 360 model, and so on.

With Microform it is possible to pack a wide variety of products, according to the following table:

|

Meats |

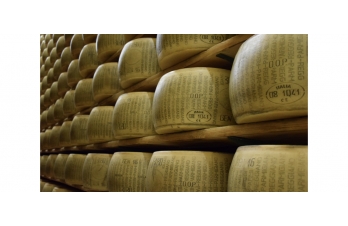

Cheese |

Rice and cereals |

Electronic components |

Sandwiches |

Mechanical components |

Pharmaceutical products |

Fish |

|

Pizza |

Poultry |

Fresh pasta |

Cured meats |

Vegetables |

Fruits |

Fish Powder and spices |

Meals to go |

Accessories available on all models:

- Product exit conveyor belt;

- Automatic label insertion device;

- Printed film photocell;

- Printed film centring devices;

- Labellers;

- Hot stamp and/or thermal transfer printers;

- Outlet roller conveyor;

- Closed circuit refrigerating units;

- Gas storage tank;

- Simplified mould changing device;

- Vibrating planes;

- Tray aligner;

- Weight control plans;

- Gravity liquid dosing unit;

- Quick film change device;

- Automatic dosing systems;

Technology Industry 4.0

It is also possible to carry out tele-service interventions at any time, to reduce machine downtime and thus operating costs. We can operate remote assistance both on the PLC and on the Control Panel, moreover we can check the executed cycles and anticipate or program the maintenance interventions according to the real needs.

Monitors the functioning, controls the work, the cycles performed, the parameters set and all the machine functions.

Main frame

Stainless steel AISI 304Useful chamber height

130 mmPasso massimo

300 mmMaximum diameter of roll

300 mm upper / 350 mm lowerWidth of film

480 mm upper / 460 mm lowerDiameter of roll support

76 mmProductivity

2-10 cycle/minuteVacuum pump

1/2x 300 mc/h (7,5 / 15 KW) + booster (5,5 KW)Electric supply

400V - 3PH+N+PE - 12/18 KWPneumatic supply

6 bar - dry and microfiltered airAir consumations

20/30 Nl/minWeight

1200/1500 kgSize

5500x1100x1990