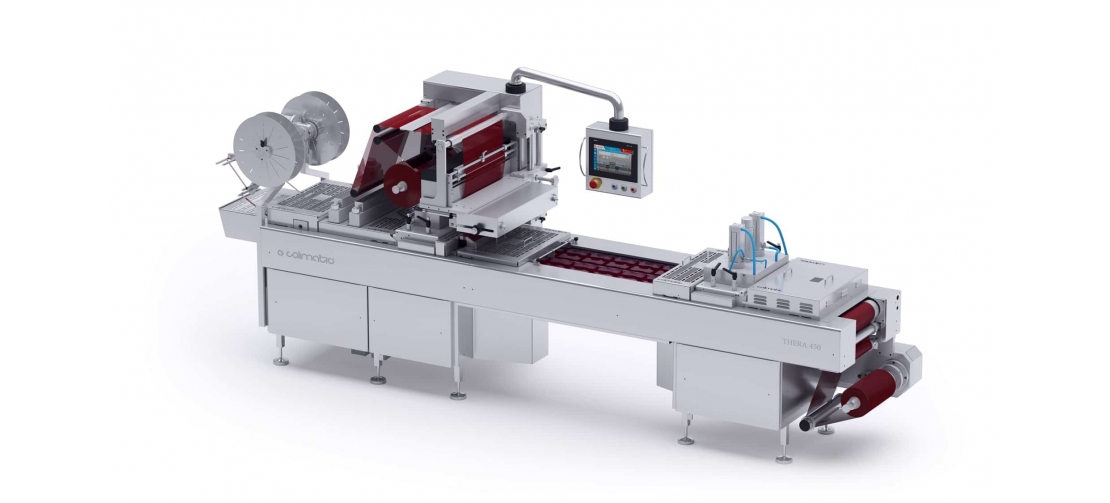

THERA 450 is a user-friendly machine with intuitive functions. It is versatile, able to work with different types of films and materials and compatible with automatic product loading systems.

It can be used for various types of applications, such as top sealing, vacuum sealing, Modified Atmosphere Packaging (MAP), gas injection, among others.

It is equipped with easily accessible hinged chambers for quick format changes, which ensures quick and easy cleaning and maintenance operations.

It also includes a 4-column lift system that consistently guarantees a high level of sealing quality thanks to the even distribution of pressure and a resistive touch control panel that allows easy HMI use in any working condition - The safety system can detect hazardous situations, stops the machine and enables the remote assistance service for faster response times.

THERA 450 also saves up to 30% of film, thanks to the vacuum and gas injection technology used in the sealing phase, which reduces the amount of film wastage to just 10 mm on the lateral, and only on the bottom film, which means packaging costs can be optimised.

The equipment is also characterised by its stainless steel structure and components, which give it not only greater strength, but also durability and consistent performance.

Production

Up to 14 cycles/minTop film reel Max diam:

400 mmBottom film reel Max diam

400 mmMachine length

4000 mmMachine width

up to 1200 mmMachine height

up to 2000 mmLoading area

700 < area > 1000Bottom film width

From 320 to 420 mmTop film width

From 300 to 420 mmPack max depth

120 mm