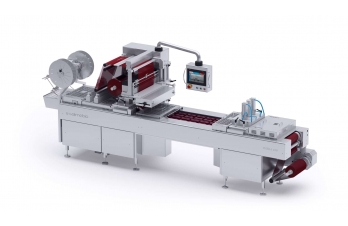

The THERA 500 combines the most advanced technology to cater for medium-high production, offering total versatility with an intelligent, integrated design. Ideal for vacuum, MAP, SKIN and SHRINK processes, this machine guarantees energy savings, easy maintenance and high hygiene and safety standards.

Eco-sustainable Materials:

- 30% saving on film waste thanks to special vacuum system

- High-efficiency gear motors

- Cooling circuit with water recycling (no water wastage)

Technology:

- 100% recyclable paper

- 100% recyclable mono-materials

- Reduced film thickness min 60 my

Key Features:

Built to Last: Durability, integrity and consistent performance

Compatibility: Synchronises with a wide variety of devices and accessoriesEasy access

Ease of Access: Maintenance and technical assistance

Ease of Use: Easier access to all machine functions, simplifying settings, machine activation and system checks.

Hygiene and Safety: Inclined machine surfaces, continuous TIG welding and strategically protected and positioned motors guarantee the highest levels of hygiene!

Energy Saving: The shared DC bus configuration allows energy to be exchanged between the axes, reducing energy wastage caused by dynamic braking resistances. This will reduce (by up to 40 per cent!) the amount of energy required (KERS - Kinetic Energy Recovery System).

It can be used for various types of applications, such as sealing, vacuum packaging, Modified Atmosphere Packaging (MAP), gas injection, among others.

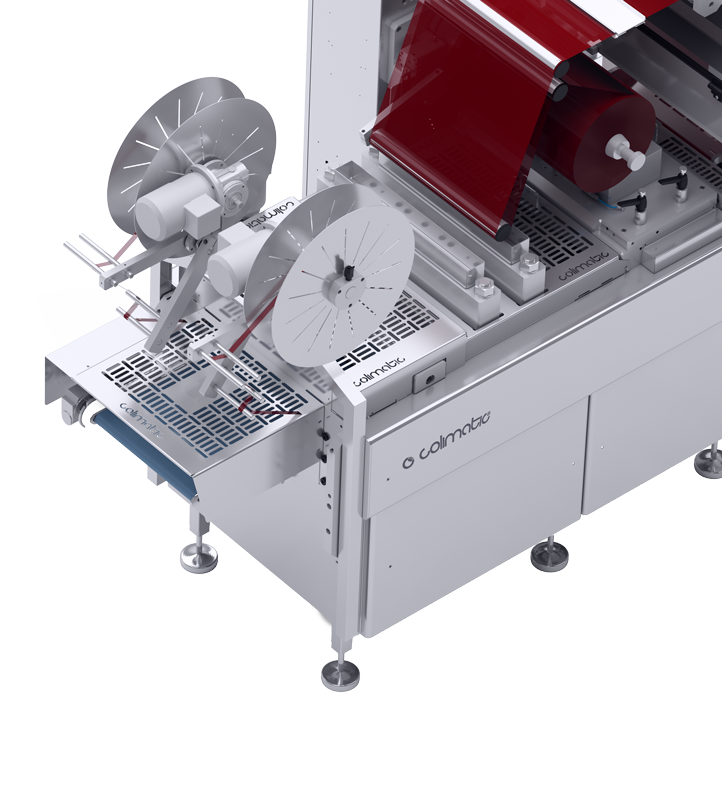

HINGED CHAMBERS

With folding opening device to allow format change, cleaning and faster maintenance operations.

RESISTIVE TOUCH OPERATION PANEL

To enable user-friendly use of the HMI in any working condition. The safety system detects hazards, stops the machine and activates the remote assistance service for faster reaction times.

FILM SAVING

Up to 30 per cent, thanks to the unique technology that uses vacuum and gas injection in the sealing phase, reducing the amount of residual material.

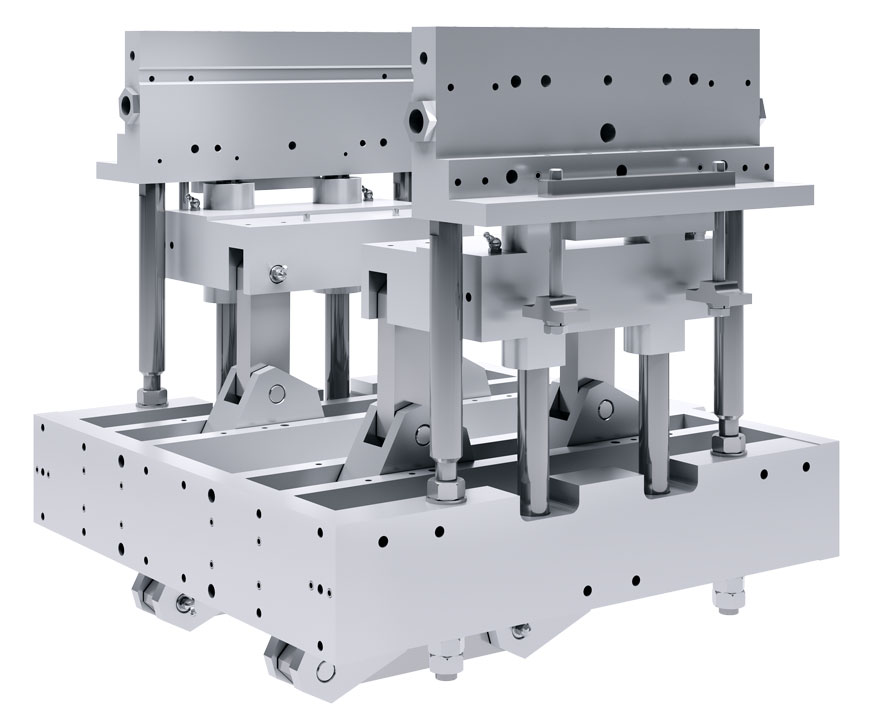

LIFTING MECHANISM

With a 4-post lifting unit that guarantees a consistently high level of sealing quality due to the even distribution of sealing pressure.

The THERA 500 is the ideal choice for companies looking for a versatile, efficient and eco-sustainable packaging machine.

Production

Up to 20 cycles/minTop film reel Max diam:

400 mmBottom film reel Max diam

400 mmMachine length

7000mmMachine width

Up to 1100mmMachine height

Up to 2000mmLoading area

1500mmBottom film width

Up to 420mmTop film width

Up to 400mmPack. max depth

Up to 120mm